Looking for the perfect shed floor that combines function with style? Your shed deserves more than basic plywood - it needs flooring that handles daily wear while looking great. Whether you store heavy equipment, work on projects, or dream of converting your space into a workshop or studio, the right floor makes all the difference. From durable epoxy coatings that resist spills to comfortable rubber mats that cushion your feet, today's shed flooring options offer amazing possibilities. You can achieve professional-grade durability without breaking the budget, and many solutions install easily as weekend projects. The best shed floors protect your investment, enhance safety, and create spaces you actually want to spend time in. Smart material choices mean your floor will last for decades while requiring minimal maintenance.

1. Epoxy Coated Concrete Floors

Transform your concrete shed floor into a showroom-quality surface with professional epoxy coating. This chemical-resistant finish creates an impermeable barrier that shrugs off oil spills, gasoline drips, and even battery acid. The two-part system bonds permanently to concrete, creating a surface five times harder than regular paint. Application involves mixing resin and hardener, then rolling the mixture across your prepared floor. Decorative flakes can be broadcast into the wet epoxy for texture and visual appeal. The result is a glossy, easy-to-clean surface that brightens your space and withstands heavy equipment. With proper preparation, epoxy floors last twenty years or more. Temperature control during application ensures proper curing, while good ventilation keeps fumes manageable.

2. Rubber Mat Flooring Systems

Why settle for cold, hard floors when rubber mats deliver comfort and protection? These recycled tire products cushion your feet during long work sessions while protecting your shed's subfloor from dropped tools and equipment impacts. Installation couldn't be simpler - just roll out the mats and they stay put through their own weight. Heavy-duty options handle everything from riding mowers to weight equipment, while lighter versions work perfectly for garden tool storage. The natural slip-resistance keeps you safe in wet conditions, and cleanup requires only sweeping and occasional mopping. Available in various thicknesses, colors, and textures, rubber flooring adapts to any shed use. Many products feature interlocking edges for seamless coverage.

3. Interlocking Vinyl Tile Design

Create custom floor patterns with snap-together vinyl tiles that install without tools or adhesives. These puzzle-piece style tiles connect through simple loop-and-peg systems, creating floating floors that handle expansion and contraction naturally. Moisture flows through small gaps between tiles, preventing trapped water that causes mold. The vinyl surface resists stains from oils and chemicals while providing comfortable footing. Wood grain, stone, and geometric patterns let you match any style preference. Damaged tiles replace individually, making maintenance simple and cost-effective. Basement-style tiles feature grooved undersides that promote airflow and prevent moisture buildup. The one-foot square format makes calculating coverage straightforward - one tile per square foot plus ten percent for waste.

4. Pressure-Treated Plywood Foundation

Build a solid base with pressure-treated plywood that resists moisture and provides stable support for heavy storage. Three-quarter inch thickness handles substantial weight loads while remaining cost-effective for budget-conscious projects. The chemical treatment protects against rot and insect damage, extending floor life significantly. Proper joist spacing every sixteen inches ensures adequate support without bounce or flex. Gaps between sheets allow for natural wood movement, while caulking seals against moisture penetration. A coat of quality primer and paint adds protection and improves appearance. This traditional approach works especially well for workshop applications where you might need to screw down equipment or workbenches. The solid surface accommodates any top covering you choose later.

5. Painted Concrete Finish

Does your concrete floor look dull and industrial? A quality paint job transforms boring gray into an attractive surface that brightens your entire shed. Start with thorough degreasing and etching to ensure proper adhesion, then apply a bonding primer designed for concrete. Two-part epoxy paint provides the best durability, though high-quality acrylic options work well for lighter use. Multiple thin coats outperform single thick applications, allowing proper curing between layers. Adding non-slip additives improves safety without sacrificing appearance. Light colors reflect more light, making the space feel larger and more welcoming. Stencils create decorative borders or safety zones. With good preparation and quality materials, painted concrete floors provide years of reliable service at minimal cost.

6. Luxury Vinyl Plank Installation

Transform your shed into a refined space with luxury vinyl planks that mimic hardwood beauty while delivering waterproof performance. These click-together planks install directly over most subfloors without nails or glue. The wear layer resists scratches from dragged equipment, while the waterproof core prevents damage from spills or humidity. Realistic wood grains and stone textures create upscale appearances that rival expensive materials. The floating installation allows for easy removal and reinstallation if you relocate. Acoustic backing reduces noise transmission, important for workshop activities. Most luxury vinyl handles temperature fluctuations better than actual wood, preventing gaps and warping. The smooth surface simplifies cleaning and maintenance while providing comfortable footing for extended periods.

7. Industrial Rubber Roll Coverage

Cover large shed areas efficiently with continuous rubber rolls that eliminate seams and gaps. These commercial-grade products handle fork lifts and heavy machinery while providing excellent traction in wet conditions. The seamless installation prevents dirt accumulation and simplifies cleaning to basic sweeping and mopping. Various surface textures include diamond plate, coin patterns, and smooth finishes for different applications. Adhesive installation creates permanent flooring, while loose-lay options allow seasonal removal for thorough cleaning. The dense rubber construction provides excellent insulation against cold concrete, making winter work sessions more comfortable. Chemical resistance protects against automotive fluids, fertilizers, and cleaning products. Standard widths accommodate most shed dimensions with minimal waste, keeping costs reasonable while maximizing coverage.

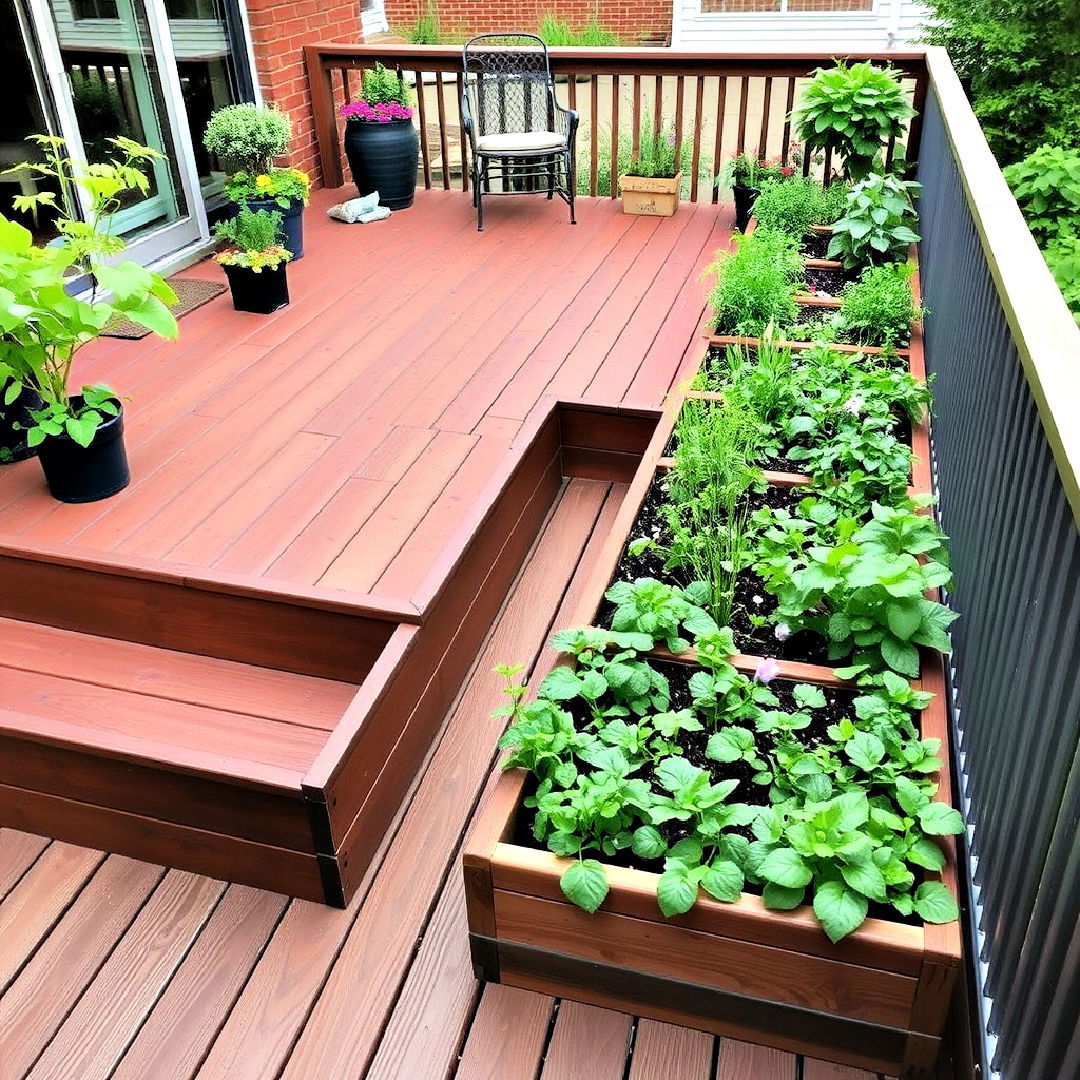

8. Composite Decking Adaptation

Looking for an eco-friendly floor that handles moisture naturally? Composite decking boards adapted for shed use combine recycled materials with excellent durability. The gaps between boards allow water drainage and air circulation, preventing trapped moisture that causes problems. Extra support joists accommodate the different spanning characteristics compared to traditional decking applications. The non-slip surface provides excellent traction even when wet, while the composite material resists rot, insects, and splitting. Various colors and textures complement different shed styles and surrounding landscapes. Installation follows standard deck procedures but requires careful attention to ventilation underneath. The result is an attractive, low-maintenance floor that handles outdoor equipment storage and workshop activities equally well.

9. Ceramic Tile Workshop Floors

Will heavy equipment damage your floor? Ceramic tile provides exceptional durability while creating professional workshop aesthetics. Large format tiles minimize grout lines that collect dirt, while through-body colors hide minor chips and wear. Proper substrate preparation prevents cracking from shed movement and settling. Epoxy grout resists stains and chemicals better than traditional cement-based products. The thermal mass helps moderate temperature swings, creating more comfortable working conditions. Various slip-resistant textures ensure safety around oils and water. While installation requires more skill than other options, the long-term durability and easy maintenance justify the effort. Borders and accent tiles add visual interest without compromising function. The smooth, non-porous surface supports rolling tool cabinets and equipment with minimal effort.

10. Raised Ventilated Base Systems

Moisture problems plaguing your current floor? Raised systems with built-in ventilation solve moisture issues while creating level, stable surfaces. Plastic grid foundations lift flooring materials above damp concrete, allowing air circulation that prevents mold and mildew. The modular components level uneven surfaces and accommodate utilities without cutting or fitting. Various top materials attach to the grid system, from plywood to specialty boards. The air gap provides excellent insulation value, reducing energy costs for climate-controlled applications. Installation proceeds quickly without mixing concrete or waiting for curing. The systems disassemble for relocation or seasonal cleaning. Weight distribution across multiple support points prevents concentrated loads that might damage underlying surfaces. This approach works especially well in flood-prone areas.

11. Stained Concrete Artistry

Why choose boring gray when stained concrete creates stunning artistic effects? Acid stains penetrate concrete surfaces, creating permanent colors that won't chip or peel like paint. Multiple colors applied in patterns create marble-like effects or geometric designs that rival expensive materials. The chemical reaction produces unique variations that make each floor one-of-a-kind. Proper surface preparation removes oils and contaminants that prevent even color development. Sealing with quality topcoats protects the stain while adding gloss levels from matte to high shine. The process requires patience as stains develop over several hours, but results last decades with minimal maintenance. Various application techniques create everything from subtle earth tones to dramatic metallic effects. Combined with decorative scoring or stamping, stained floors transform ordinary sheds into extraordinary spaces.

12. Foam Tile Comfort Zones

Standing for hours on hard floors takes a toll on your body, but foam tiles provide cushioned relief where you need it most. These puzzle-piece mats connect easily around workbenches and frequent-use areas while remaining removable for cleaning. The closed-cell foam resists oil and water absorption while providing excellent shock absorption. Various thicknesses accommodate different comfort needs, from basic fatigue relief to serious impact protection. Wood grain and solid color patterns complement existing flooring while creating defined work zones. The lightweight material handles easily, allowing quick reconfiguration as needs change. Beveled edges prevent tripping hazards when used as accent areas. While not suitable for heavy equipment, foam tiles excel in areas where comfort and safety matter most. Easy replacement keeps long-term costs minimal.

13. Polished Concrete Elegance

Can industrial materials look elegant? Polished concrete proves they can, creating mirror-like surfaces that rival marble. The mechanical grinding process removes surface imperfections while progressively refining the texture to desired smoothness levels. Diamond polishing compounds create incredible shine that reflects light beautifully. The dense surface resists stains and damage while requiring only basic cleaning to maintain appearance. Various aggregate exposure levels create different visual effects, from smooth cream finishes to dramatic stone-flecked surfaces. Decorative saw cuts add geometric patterns that complement modern shed designs. The process works on new or existing concrete, making it viable for renovation projects. While requiring professional equipment, the results justify the investment for high-end applications. The seamless surface supports any type of equipment while looking absolutely stunning.

14. Recycled Rubber Solutions

Environmental consciousness meets practical performance in recycled rubber flooring made from discarded tires. These sustainable options divert waste from landfills while creating durable, comfortable surfaces. The material naturally resists oils, chemicals, and weather while providing excellent traction. Various formats include interlocking tiles, continuous rolls, and custom-cut mats for specific applications. The cushioned surface reduces fatigue during extended work periods while protecting dropped tools and equipment. Installation typically requires no adhesives, allowing easy removal and reinstallation. Weather resistance makes these products suitable for partially covered or unheated sheds. The dark colors hide dirt and stains while maintaining professional appearance. Many recycled products cost less than virgin materials while delivering equal or superior performance, making them smart choices economically and environmentally.

15. Vinyl Roll Simplicity

Sometimes simple solutions work best, and vinyl rolls provide waterproof protection with minimal fuss. These single-piece installations eliminate seams where dirt and moisture accumulate. The flexible material conforms to minor surface irregularities while maintaining smooth, easy-to-clean surfaces. Various patterns include wood planks, stone textures, and solid colors to match any preference. Adhesive installation creates permanent flooring, while temporary applications use double-sided tape for seasonal use. The lightweight material ships economically and installs without heavy equipment. Damage repair involves patching rather than replacing entire sections, keeping maintenance costs low. The smooth surface supports rolling equipment while providing comfortable footing for standing work. Standard roll widths accommodate most shed dimensions with minimal waste, making coverage calculations straightforward.

16. Metallic Epoxy Sophistication

Ready to make a statement? Metallic epoxy systems create three-dimensional effects that change appearance based on viewing angle and lighting. Multiple metallic colors swirl together during application, creating unique patterns impossible to replicate exactly. The base epoxy provides chemical resistance and durability while the metallic additives deliver stunning visual impact. Special tools create flowing, marble-like patterns or more controlled geometric designs. The seamless surface resists stains and damage while reflecting light beautifully. Professional application ensures proper mixing and timing for optimal results. The extra thickness provides superior impact resistance compared to standard epoxy systems. UV-stable topcoats prevent color fading in naturally lit sheds. While premium pricing reflects the sophisticated chemistry, the results rival expensive decorative concrete or stone surfaces at a fraction of the cost.

17. Laminate Plank Warmth

Does your shed feel cold and unwelcoming? Laminate planks add warmth through realistic wood and stone visuals while delivering practical performance. The engineered construction resists moisture better than solid wood while maintaining authentic textures and colors. Click-together installation proceeds quickly over most subfloors without nails or glue. AC ratings indicate durability levels, with higher numbers suitable for heavy commercial use. Foam underlayment improves comfort and sound dampening while accommodating minor subfloor imperfections. The smooth surface simplifies cleaning and maintenance while resisting stains from common shed substances. Various plank sizes and installation patterns create custom appearances that complement any shed style. While not waterproof like vinyl alternatives, quality laminate handles normal moisture levels well with proper installation techniques.

18. Concrete Tile Durability

Want the look of individual tiles with concrete's strength? Concrete tiles combine decorative appeal with exceptional durability. The dense material resists chemicals, impacts, and heavy loads while maintaining attractive appearances. Various textures and colors mimic natural stone, brick, or create unique contemporary looks. The substantial thermal mass moderates temperature swings, creating more stable working conditions. Proper installation over stable substrates prevents cracking and ensures long service life. Sealed surfaces resist stains while maintaining easy cleaning characteristics. Individual tile replacement addresses damage without affecting surrounding areas. The weight requires adequate structural support but provides stability that prevents movement under heavy equipment. Various sizes accommodate different space scales and design preferences while maintaining classic proportions.

19. Hybrid Coating Systems

Looking for maximum performance? Hybrid systems combine different materials to achieve superior results. Polyurethane-modified epoxy delivers enhanced flexibility and UV resistance compared to standard epoxy. These systems handle thermal cycling and minor structural movement without cracking or delamination. The chemistry creates harder surfaces with better chemical resistance than single-component alternatives. Various textures from smooth to highly textured accommodate different safety and aesthetic requirements. Professional mixing ensures proper component ratios for optimal performance and appearance. The extended working time allows larger installations without visible lap marks. Enhanced adhesion properties work over properly prepared concrete, wood, and steel substrates. While more expensive than basic systems, the superior performance justifies costs for demanding applications that require maximum durability and appearance retention.

20. Natural Stone Character

Does your shed deserve natural beauty? Stone flooring brings timeless elegance with unmatched durability. Slate, granite, and limestone offer different colors, textures, and performance characteristics for various applications. The natural variation creates unique patterns impossible to replicate artificially. Proper installation over stable substrates prevents cracking while ensuring level surfaces. Sealing protects porous stones while enhancing natural colors and patterns. The thermal mass provides excellent temperature stability, important for climate-sensitive storage or workspace applications. Various surface finishes from polished to rough-textured accommodate different safety and aesthetic needs. While requiring higher initial investment, natural stone floors last indefinitely with basic maintenance. The sophisticated appearance elevates shed spaces to architectural quality while providing surfaces that improve with age and use.

Conclusion:

Creating the perfect shed floor involves balancing durability, aesthetics, and budget to match your specific needs. Whether you choose industrial-strength epoxy for chemical resistance, comfortable rubber mats for workshop use, or elegant natural stone for architectural appeal, today's options deliver both function and style. Consider your shed's primary purpose, local climate conditions, and long-term maintenance preferences when making decisions. Professional installation ensures optimal performance for complex systems, while many options accommodate confident DIY installation. Quality materials and proper preparation create floors that last decades while maintaining attractive appearances. The right flooring choice transforms ordinary storage spaces into functional, enjoyable areas that enhance your property value and daily life, proving that foundation investments pay dividends for years to come.

Leave a Reply